Introduction

The global surge in plastic production over the last 50 years has led to a concerning increase in plastic waste, severely impacting the environment. This blog explores the “Revive Green Earth” project, which aims to address this issue by employing pyrolysis, a waste-to-energy technology, to convert plastic waste into bio-fuel as a sustainable alternative to fossil fuels.

Literature Survey

Research on co-processing polyethylene and polypropene into petroleum products has shown promising results. This method offers a feasible approach to converting plastic materials into valuable petroleum products.

Objectives

The primary goal of the project is to raise awareness about plastic waste and assess the feasibility of converting it into cost-effective petroleum products. This could potentially lead to cheaper alternatives to conventional petroleum products.

Different Grades of Plastic

The project focuses on identifying and utilizing specific grades of waste plastics (Grade 1, 2, and 4) for the conversion process.

Petrochemistry

Understanding the petrochemical process is crucial for the project. Crude oil undergoes cracking, resulting in valuable compounds like ethylene, propylene, benzene, and more.

Compounds We Use

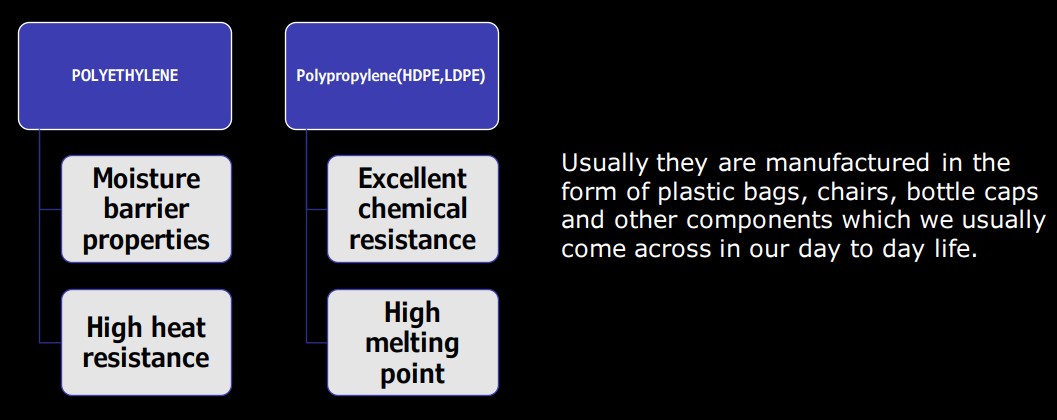

The project utilizes recycled polyethylene and polypropylene compounds, obtained from waste plastics, for the production of crude oil.

Properties

Polyethylene and polypropylene exhibit desirable properties, making them suitable for various applications such as plastic bags, chairs, and bottle caps.

Methodology

The experimental process involves the identification, treatment, and conversion of waste plastics through pyrolysis, simple distillation, and fractional distillation.

Explanation about 3 Important Processes

The blog elaborates on the crucial processes involved in the experiment: pyrolysis, simple distillation, and fractional distillation.

Pyrolysis

Explaining the chemical reaction breaking down larger molecules into smaller ones at high temperatures.

Simple Distillation

Detailing the procedure of separating liquids with different boiling points, crucial for plastic distillation.

Fractional Distillation

Describing the separation of components in crude oil based on boiling points, leading to the production of liquid petrol.

Steps :

- Crude oil is introduced into the reactor.

- High-pressure steam is used to heat the crude oil mixture.

- Boiling occurs, leading to the formation of vapor.

- Various substances enter the vapor phase.

- The vapor rises up in the fractional distillation column containing several plates.

- The column plates have holes allowing vapor to pass through.

- Temperature is intentionally kept low at the top of the fractionating column.

- Components with the highest boiling point condense in the lower part of the column.

- Substances with a low boiling point condense at the top of the column.

- Condensed vapors or liquid fractions are removed from the sides of the column.

- Collected liquid fractions can undergo further cooling through condensers.

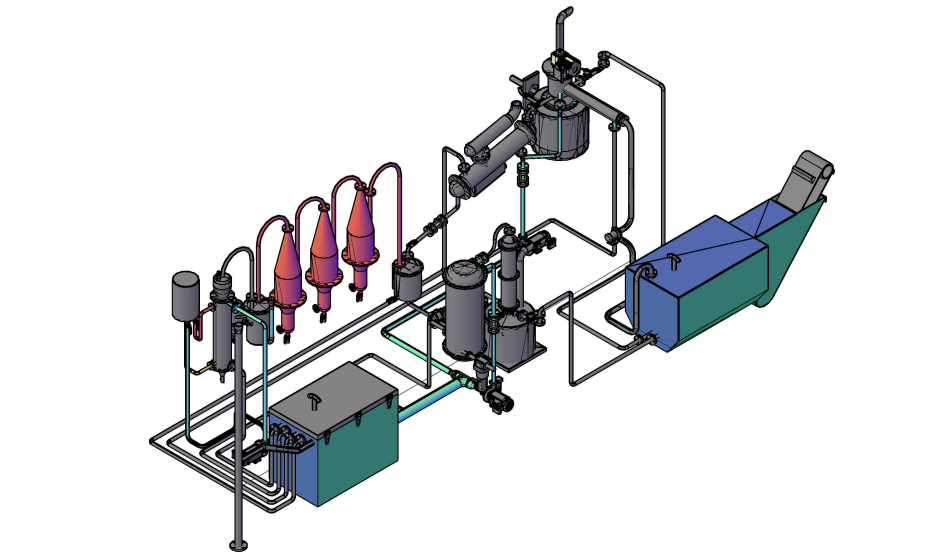

Setup of the Proved Experiment

Detailing the collection, identification, and treatment of waste plastics, along with the plastic extrusion line and various condensers used in the setup.

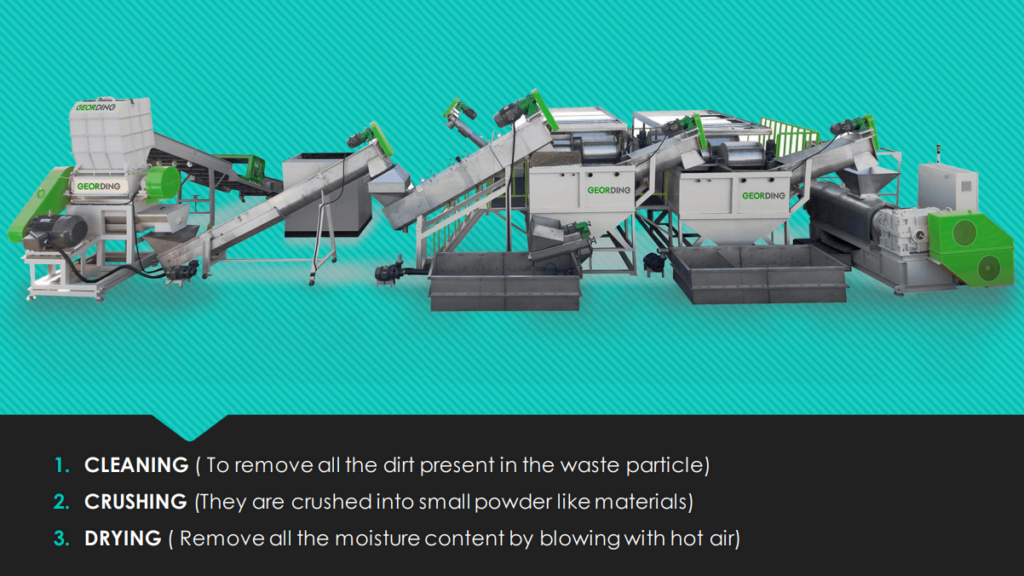

Collection & Identification of Waste Plastic:

- The process of collecting waste plastic is relatively straightforward compared to other types of waste. Plastic waste is abundantly available and can be sourced in large quantities from various locations such as households, roadsides, hospitals, hotels, etc.

- Waste plastics are separated during the collection process, with a specific focus on identifying different grades of waste plastic. Grades 1, 2, and 4 are primarily targeted for use in the subsequent processes.

Octane Rating of Gasoline:

- Gasoline with an octane rating of 91 contains a mixture of hydrocarbons and additives that perform similarly to a blend of 91% iso-octane and 9% heptane in this test.

- Qatar typically used gasoline with different octane ratings, such as 91 octane and 95 octane (Based on September 2021 study).

- Gasoline with an octane rating of 95 contains a mixture that performs similarly to a blend of 95% iso-octane and 5% heptane in the same test.

- In our method, we obtain 97.6% iso-octane fuel, suitable for consumption in automobiles after adding additives (catalyst) to increase its efficiency.

Treatment of Trace Gases and Toxic Compounds:

- The various trace gases formed are mainly CO due to incomplete combustion, SO2 due to the presence of sulfur additives in plastics, various nitrogen oxides like nitrogen dioxide, and some particulate matter.

- In these, CO, SO2, and NO2 are separated using an ORSAT analyzer.

Final Product:

- The above experiments mentioned (1 kg waste plastic into 820mg fuel) are conducted on a small scale to obtain the exact value of every resource used in this process.

- The entire process, when scaled up, has the potential to be highly profitable, as even a small quantity of plastic waste can produce a significant amount of fuel. This economic viability becomes a key selling factor for the product.

Physical Properties of Petrol Grade of Waste Plastic

Presenting the chemical tests and results of the produced petrol, including appearance, color, specific gravity, octane rating, and other essential parameters.

Application of Project and Future Work

Discussing potential applications of the obtained fuel, refining processes, and the scope for setting up small or large-scale industries for local fuel production.

- The fuel obtained from this project holds the potential for utilization in vehicles, contributing to sustainable energy solutions.

- To make the fuel suitable for widespread use, a refining process is necessary, and this refinement can take place in industrial establishments.

- Based on the positive results achieved, there is an opportunity to establish small-scale industries that focus on the production and refinement of this fuel.

- Given the existing demand for crude oil, this project presents an avenue to set up both large and small industries, producing fuel locally at more economical rates.

- The local production of fuel at reduced costs directly benefits the national economy, promoting self-sufficiency and economic growth.

Conclusion

Summarizing the potential benefits of the “Revive Green Earth” project, from waste plastic control to the development of a new fuel source, and its positive impact on the national economy. The implementation of this project can lead to a sustainable solution while creating numerous opportunities for development.

By converting waste plastics into a valuable resource, the project not only addresses plastic pollution but also contributes to the development of sustainable energy solutions. The success of “Revive Green Earth” can be a catalyst for positive change, showcasing the potential of waste-to-energy technologies in building a greener and more sustainable future.

👍🏻👍🏻👍🏻👍🏻👍🏻